Differences Between Pigment & Dye Inkjet Film

IMPORTANT FILM and INK INFO

IF YOU SWITCHED YOUR INK DELIVERY SYSTEM and now your film results are different, reset back to the default settings in AccuRIP and print a Droplet Weight Density Test Print. The previous settings many no longer be your best settings. This test print will (1) provide new settings best for film printing, (2) showcase that you should try using a dye film for best results.

Any price difference in film brands/types might initially seem worthwhile despite struggling a bit, but the difference is likely minimal per sheet or over the length of a roll. A couple of bad files and savings are gone, and could be very costly due to production downtime or wasted screens.

Know what film to use when using DYE Inkjet Ink…

There are different brands/styles of film. Even from one manufacturer their films can have different properties and abilities. Always choose the best possible because film is what we use to expose our screens. Don’t forget, we are “screen” printers. If your screens are second rate, your prints will be too.

Having the correct emulsion layer on film helps speed the drying process, and keeps edge quality high reducing dot gain. Avoid using films with a thin, almost “clear” appearance and never use a “non-waterproof” film. Dye ink (strongly recommended over Pigment) is water-based so match it with dye film. The name alone “non-waterproof” should tip you off that it’s not the best product for your needs. The slightly cloudy emulsion of dye film does not affect the exposure process, yet it grabs a hold of the ink sprayed onto the film during output.

Pigment and Dye INK are not the same. They are not even close. They require a very different film to perform at their best. Dye ink is the screen print industry standard for film making. When using dye ink use film developed to handle water based dye ink and not one developed for pigment ink. Sounds simple, but it is a very common issue throughout our industry.

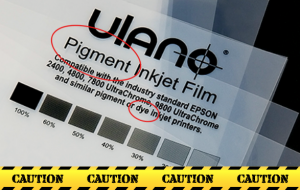

A very common mistake in the screen print industry is not necessarily a deliberate decision made by a screen printer. There is no technical data to support the claims that one film can handle water-based dye ink AND encapsulated pigment ink the same manner. It’s likely a marketing plan of those that either do not want to produce two different styles of film, or don’t want to stock and sell two different types. Unfortunately this is all too normal in the screen print industry. Here’s an example, Ulano, the manufacturer of many great products, made a decision years ago to discontinue a film line called DIJF (Dye Inkjet Film) keeping only the PIJF (Pigment inkjet film). With the incredible increase since this change in the use of DYE ink over pigment ink the need to provide this user information keeps growing.

Freehand was witness to this change many years back and certainly concerned about what it meant (and still means) for film production quality and reliability. We live it daily as we support our users. Many screen printers continue to use the wrong product combinations, sold on the idea that film produced for pigment ink can actually handle the dye ink they use as well. Now you understand that this is not good advice. You can see it daily in the slow drying, flooding, lack of detail and the milky white appearance on the back of the film. The milky appearance is the emulsion swelling from the water in the dye ink, breaking away from the polyester carrier sheet. What fills that gap? You guessed it, ink. Ink keeps on gaining as it slowly dries. This is a big reason most screen printers can not archive their best films. They are a one off process. What a waste.

So, when using dye ink look for film developed specifically for dye ink. Freehand’s DarkStar film for Dye Ink is one of those products. Ask your reseller for a specific dye ink brand. If they point you to a dual purpose film, consider making a change.